On June 25, 2025, the Metalot@Work session held at the Future Energy Lab in Budel, Netherlands, brought together experts, researchers, and industry professionals to explore the potential of metals beyond iron as sustainable energy carriers. The hybrid event, hosted both in-person and online, showcased groundbreaking developments in aluminum, magnesium, zinc, and iron-based solutions, highlighting their roles in the global energy transition. With almost 100 participants present both physically and online, the session underscored the growing international Metal Power Community and its commitment to advancing metal-based energy solutions.

Note: All presentations can be downloaded at the bottom of the page.

Raoul Voeten, Managing director Metalot opened the session by emphasizing the shift from technology-driven discussions to market-driven solutions in the energy transition. He highlighted the importance of modesty in presenting metal fuels as part of a broader solution, fostering collaboration and market traction. Safety announcements and logistical details were shared, ensuring a smooth hybrid experience for both onsite and online attendees.

Jeff Bergthorson (McGill University) provided a holistic overview of metals as recyclable energy carriers, focusing on alternatives to iron, such as aluminum, magnesium, and zinc. He discussed McGill’s advancements in the wet cycle, utilizing supercritical water reactors to process millimeter-sized metal slugs, producing heat and hydrogen without the safety risks of nanoscale powders. Bergthorson highlighted the high energy density of these metals, comparable to fossil fuels, and their potential in applications like remote mining. Techno-economic and lifecycle analyses showed that aluminum, when produced with inert anodes, could be cost-competitive with liquid hydrogen and ammonia, with significantly lower CO2 emissions.

Thijs Hazenberg (TU Darmstadt)delved into the fundamentals of aluminum steam combustion, noting its higher energy density compared to iron, which reduces transport and storage costs. His research focuses on controlling nanoparticle formation to enhance recyclability. By combusting aluminum in steam at elevated pressures (6–7 bars), Hazenberg aims to deposit aluminum oxide on the particle surface, improving recapture efficiency. While high-pressure steam experiments are still in development, preliminary models show promising results, validated against existing research, with applications for heat and hydrogen production.

Yvonne Bäuerle (OST – Ostschweizer Fachhochschule, online) presented the Horizon Europe Reveal project, which leverages aluminum-water reactions to meet winter heat and electricity demands in buildings. The project uses CO2-free aluminum granules produced via low-temperature electrolysis, requiring only 0.75 cubic meters of storage to deliver 15 MWh/m³. Their 4 kW prototype generates 3 kWh of heat and 1 kWh of electricity per kilogram of aluminum, with hydrogen converted directly via fuel cells. Bäuerle projected a cost of $0.30/kWh by 2030, competitive with current market rates, and highlighted the system’s potential for seasonal energy independence in multifamily homes.

Michiel Kruijf introduced ZemQuest’s aluminum-air battery technology, designed for emission-free energy in remote construction sites and heavy machinery. Using simple aluminum plates, the system achieves 2.5 kWh/kg, offering five times the endurance of lithium-ion batteries at a lower cost (€0.25–1.30/kWh). The modular, scalable design supports applications in mining, harbors, and agriculture, with a fully circular process that recycles aluminum hydroxide. Kruijf emphasized partnerships with VDL, Quintec Energy, and Norsk Hydro to scale the technology, targeting a €200M market within five years.

Cornelius Schonnenbeck (Université de Haute Alsace) explored magnesium-air combustion, highlighting magnesium’s abundance and comparable energy density to hydrocarbons. His team stabilized magnesium flames in a 5–25 kW reactor, capturing over 90% of magnesium oxide particles. While nanoscale particle formation poses challenges, agglomeration improves recapture. Schonnenbeck addressed NOx emissions, noting that near-stoichiometric conditions and flue gas recirculation can minimize them, making magnesium a viable clean energy source for heat applications.

Ellen Molleman discussed Nyrstar’s zinc smelting operations in Budel, producing 300,000 tons of zinc annually with high energy efficiency. She introduced a novel flowsheet to recover critical metals like germanium and produce clean jarosite (iron sulfate) and lead-silver concentrates. While jarosite could serve as a feed for iron fuel processes, sulfur content poses challenges. Molleman also explored zinc powder combustion for heat and hydrogen, but current costs (2.5 times higher than electric boilers) make it less viable, though future hydrogen production could be promising.

Roy Hermanns (TU/e) presented the WISE project, investigating iron sludge from Dutch water treatment (90,000 tons/year) as a potential iron fuel source. After drying and reducing the sludge, which contains ~50% iron, the project achieved up to 80% reduction efficiency at 700°C. Groundwater sludge outperformed surface water sludge due to lower impurities. Hermanns highlighted the need for higher-temperature tests to optimize reduction, with ongoing trials at Pomaton to assess economic viability and scalability.

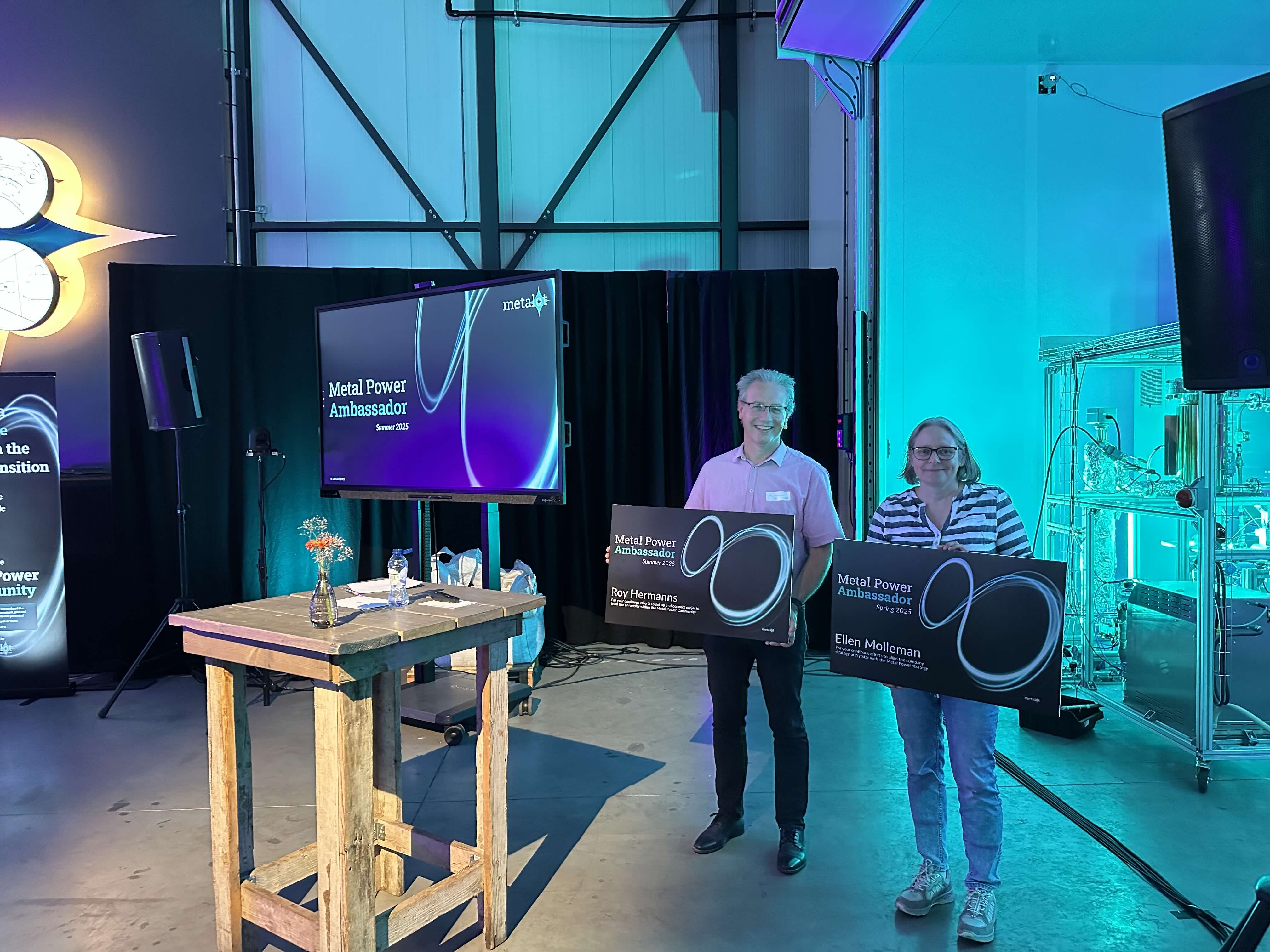

The session concluded with the presentation of Ambassador Awards to Ellen Molleman and Roy Hermanns for their significant contributions to the Metal Power Community. Their work in facilitating projects and advancing the ecosystem was celebrated, encouraging further collaboration and innovation.

The Metalot@Work session demonstrated the diverse potential of metals like aluminum, magnesium, zinc, and iron in addressing energy storage and decarbonization challenges. From fundamental research to practical applications, the speakers showcased how these metals can complement iron fuel in achieving a sustainable energy future. The event fostered vibrant discussions, both onsite and online, reinforcing the community’s commitment to scaling metal-based energy solutions.

For more information on upcoming Metalot@Work sessions: click here and to join the Metal Power Community, check out this page.

Stay tuned for future events as we continue to explore innovative pathways for the energy transition.